Greenyard Enhances Packaging Precision and Cuts Waste With Mettler-Toledo Technology

Greenyard Frozen Belgium has achieved a notable improvement in packaging accuracy and operational efficiency at its Westrozebeke facility through the integration of Mettler-Toledo’s intelligent checkweighing systems. The company, which packages millions of frozen fruit and vegetable products each year for domestic and international markets, adopted the technology to address persistent issues of overfilling and product waste on its high-speed lines.

Excess fill levels had long posed a challenge, with Greenyard adding a 40-gram margin to each one-kilogram bag to avoid underweight packages. The cumulative effect amounted to substantial product losses over time. Manual adjustments failed to maintain consistency, leading the company to trial an automated solution that could deliver greater precision.

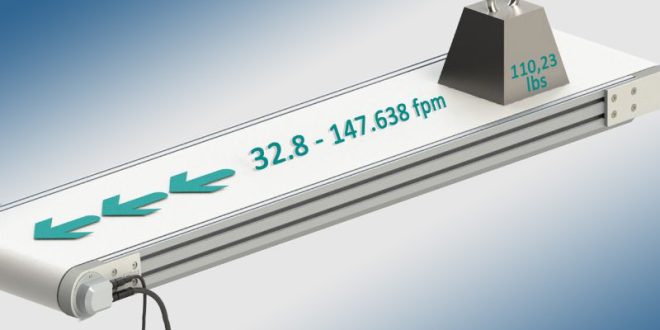

The implementation of Mettler-Toledo’s C33 PlusLine checkweigher, equipped with a smart fill level adjustment function, allowed Greenyard to continuously monitor package weights and automatically fine-tune filling margins in real time. The system reduced the average overfill per bag from 40 grams to just 10 grams while maintaining compliance with target weights.

According to Dominiek Vierstraete, Technical Manager in Greenyard’s packaging department, the outcome exceeded expectations. “We have used checkweighers and metal detection systems from Mettler-Toledo for many years. We initially tested the smart level fill adjustment feature on one of our newer checkweighers. The results were so convincing that we decided to replace four older devices and integrate this function across all packaging lines,” he said.

Deployment required calibration to account for different product characteristics, such as peas versus cauliflower pieces, and was supported by on-site assistance and operator training from Mettler-Toledo. Once installed, the system automatically adjusted fill weights without manual input, maintaining output within close range of target specifications.

The impact on production efficiency was immediate. On one line, overweight levels fell from 0.69% to 0.14%, and from 0.30% to 0.11% on another. “That may not seem like much but calculated annually over large volumes, it represents significant quantities of product no longer packaged unnecessarily. This benefits both cost and waste reduction,” Vierstraete explained.

Beyond product savings, Greenyard reports that the new systems require less manual intervention and have streamlined line performance. “We can control the excess weight much better and stay closer to the desired filling weight. This saves product, prevents waste, and contributes to a more efficient process. Ultimately, it is an investment that pays for itself quickly,” said Vierstraete.

Mettler-Toledo emphasises that such results are typical for manufacturers implementing automated product inspection solutions. “Margins are under pressure and every gram counts—companies can save substantially with smart technology. On average, the investment is recouped within a few months, depending on the product and the line,” said Mari Bögels, Account Manager at Mettler-Toledo Product Inspection.

The project’s success also highlighted the importance of close collaboration between supplier and manufacturer. “Our role goes beyond installation; by working closely with the Greenyard team we support them to get the most out of their smart checkweighing solutions every day,” said Janus Dumelie, field service technician at Mettler-Toledo Benelux.

Greenyard’s experience underscores how intelligent weighing systems can deliver measurable efficiency gains in large-scale food production, reducing raw material use and improving sustainability.