PACE and JT Hopkins & Sons Celebrate 30-Year Partnership with New Packing Line

PACE Mechanical Handling and JT Hopkins & Sons are celebrating three decades of collaboration with the installation of a new high-performance potato packing line, reinforcing a partnership that began in 1995.

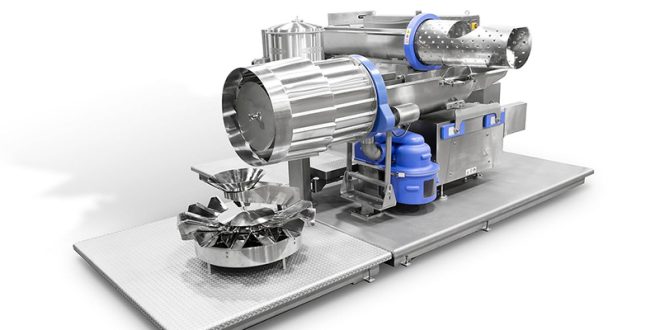

The upgrade, commissioned earlier this year at JT Hopkins & Sons’ Carsaig Farm facility, includes PACE’s latest weigher, stitcher, and sack placer. The system enables packing speeds of up to 360 sacks per hour for 25kg chipping potatoes, significantly increasing throughput and operational efficiency.

The two companies first joined forces in the mid-1990s when PACE supplied a single-head weigher and stitcher system to replace an aging palletiser. A decade later, in 2005, the line was upgraded with a double-head weigher. Now, twenty years on, the latest technology marks a new chapter in the long-standing relationship.

“We’re very impressed with the new line. It is fast, efficient, and very well made,” said Richard Hopkins, who leads the family business. “PACE has made several upgrades since we last improved the line, and the difference in performance is significant. By upgrading, we’ve also been able to relocate one of our team members to other duties, which improves our productivity.”

Founded in the 1940s, JT Hopkins & Sons is a diversified agricultural enterprise growing potatoes, carrots, and combinable crops, in addition to maintaining a cattle operation and haulage business.

PACE Mechanical Handling, founded in 1996, designs and manufactures automated packaging and palletising solutions for the agricultural and food processing sectors. Its portfolio includes the Gemini twin-head weigher, Orion Weigher, Orion Weigher and sack placer, and the CBC sack placer and stitcher line.

Nick Cesare, Managing Director at PACE, expressed pride in the relationship with JT Hopkins & Sons. “As well as developing efficient and reliable packing solutions, we try our best to build long-term relationships with our customers,” he said. “I am delighted to have marked three decades of working with JT Hopkins & Sons and was thrilled when Richard asked us to quote for upgrading the line we installed in 2005.”

Prior to making the investment, Hopkins conducted a site visit to another grower operating the same PACE system. “We wanted to make sure we chose the right company,” he said. “We like Nick and the quality of his machines, but it was important to do our due diligence. Seeing the new PACE system in action helped us make an informed decision.”

The latest installation highlights the growing emphasis on automation in mid-sized farming operations, as producers seek greater efficiency, labour optimisation, and consistency in output.